The glass cosmetic bottle set is attractive and gives a classy look. Glass is cheap and beneficial to environmental protection. It can be used in high-grade or low-grade cosmetics without fading or deformation. Glass is inert and impermeable, and glass cosmetic bottles can ensure that cosmetic products remain intact and maintain product integrity. Yafu Glass is a manufacturer of glass bottles and jars, we provide different styles of glass cosmetic bottle sets.

Glass Cosmetic Bottle Set Wholesale

Glass cosmetic bottle set is an eco-friendly and sustainable alternative to plastic packaging. For wholesale buyers, there are several benefits to using a cosmetic glass bottle set. They are durable, reusable and recyclable many times.

Cosmetic Glass Bottle Advantages

- Environmental friendly: They are environmentally friendly and sustainable. The glass is made from natural materials and is 100% recyclable. This means it can be recycled multiple times without loss of quality or purity. Glass cosmetic bottle sets have a much lower environmental impact than plastic packaging. The glass is non-toxic and does not release harmful chemicals into the environment.

- Durable: The glass cosmetic bottle set is durable. They don’t break easily, which means they can be used over and over again. This makes them an affordable and practical option for wholesale buyers.

- Good Sealing Effect: the glass cosmetic bottle set is airtight. This means they maintain the quality and potency of beauty products, ensuring cosmetic ptoducts stay fresh and effective for longer.

Costmetic Glass Bottles Vs Plastic Bottles

Glass cosmetic bottle set is mainly used in skin care products (cream, lotion, essence, toner). The glass cosmetic bottle has a good feel and texture. And in consumers’ impression, skincare and beauty products in glass bottles and jars reflect the quality of the product, and glass material packaging represents luxury.

- Glass bottles have irreplaceable advantages in cosmetic packaging containers. Thorough, pure, noble and elegant, is the charm of glass bottles. Compared with plastic bottles, the heavy feeling of glass cosmetic bottles and jars can effectively enhance the brand’s grade and make consumers more trustworthy.

- When producing plastic bottles, it is impossible to achieve the effect of matte and frosted surface through mold surface treatment. Plastic cosmetic bottles can only be processed by post-processing oil injection, which is much less effective and costs quite a lot.

Cosmetic Glass Bottle Manufacturer

Yafu Glass is a comprehensive company integrating development, production and sales as a professional glass products manufacturer. Our glass bottles have clear bottles, frosted bottles, and colored bottles.

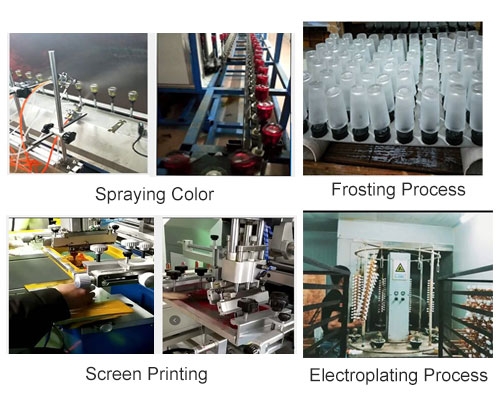

Compared with the flat glass bottle, the frosted glass bottle is elegant and gorgeous, with a good fog feeling, good decorative shading effect, and more technical decoration functions. Glass products provide a full range of services, from mold opening, sample, production, frosting, screen printing, spraying, bronzing, and electroplating to delivery.

Glass Cosmetic Bottle Screen Printing Process

Screen printing, as a graphic and textual label processing process for packaging products, has an important impact on product image. There are usually two types of glass bottle screen printing.

One is high-temperature ink screen printing, which is characterized by not easy decolorization and dull color. But purple toning is more difficult. The other is low-temperature ink screen printing, which has brighter color and higher requirements for ink. Otherwise, the color is easy fall off, and attention should be paid to the disinfection of the bottle.

Glass Bottle Hot Stamping Process

Hot stamping is the process of transferring the metal foil to the surface of the glass cosmetic bottle set according to the hot stamping stencil. With a certain pressure and temperature, it uses the template installed on the hot stamping machine to make the printed matter and the hot stamping plate press together in a short time.

If you are interested in our products, please send your requirements!